Production Line Schedule Workbench Excel Loader 18.22.1.10

This loader provides a simple, efficient and user friendly interface to maintain line schedules in QAD and minimizes data maintenance and processing time. It is a powerful and effective production planning and capacity management tool that requires minimal support and maintenance.

Overview

Line Schedule Workbench loader allows to:

- Create a simulated repetitive schedule (line schedule) for a specific production line and site combination

- Have the system automatically modify line schedules based on the capacity constraints of the specified production line

- Update or create repetitive schedules from MRP planned orders

For a user Line Schedule Workbench Excel Interface is a simple, efficient and user friendly tool to maintain line schedules in QAD that minimizes data maintenance and processing time. For a business it is a powerful and very effective production planning and capacity management tool with minimal human resources involved in its support and maintenance.

User Authentication

User Authentication is based on QAD Authentication logic (user id, password, menus and site security). To be able to update data in QAD database with this interface user should have a valid QAD UserID, have access to 18.22.1.10 Line Schedule Workbench menu and be authorized to update selected site.

Functionality

The goal of Line Schedule Workbench Interface is to be a single access point for production scheduling and capacity planning. Its functionality includes:

- Download from QAD into Excel details on line schedules and capacity utilization

- Upload from Excel into QAD changes to production line schedules

- Report on planned production orders

Note: This version of Line Schedule Workbench interface does not include Production Orders Approval functionality

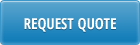

Line Schedule Workbench Interface is designed as an Excel spreadsheet with dedicated areas for selection / control criteria, data section and action buttons.

This version of interface does not use divisible schedule quantity for a workbench session. It is as if 18.22.1.10 Line Schedule Workbench QAD function was run with “Multiple” parameter set to 0.

Line Schedule Download

When user clicks on Download Line Schedule button the following is happening:

1) Old data in the data section are erased;

2) User access to 18.22.1.10 Line Schedule Workbench and site specified in the selection criteria are verified. If user is not authorized to update line schedule error message “User is not authorized to update line schedule for site XXXX ” is displayed;

3) Selection criteria are validated. Site and production line should exist. Line should be assigned to a selected site. Start Date should be blank or a valid date. If date field is blank it will be assumed that its value is equal to first available date in the schedule master.

4) If validation is successful the following line schedule data are downloaded from QAD into Excel:

- Sequence

- Item Number

- Quantity Scheduled

- Quantity Completed

- Unit of Measure

- Due date

- Units per Hour

- Line load

- Line Capacity

- Line Utilization

Line load (number of hours necessary to produce scheduled quantity) is calculated as scheduled quantity divided by Units per hour.

Line capacity is calculated as total capacity per day: duration of all shifts plus adjustments, if any.

Line Utilization is calculated as a percent of line load from the total line capacity (line load / line capacity * 100)

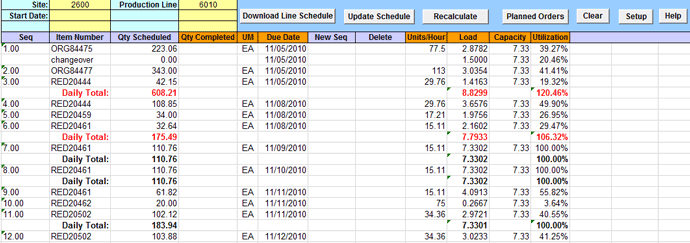

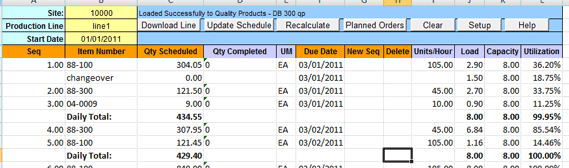

Totals for quantity scheduled, line load and line utilization are calculated for each date. Total lines are displayed with value “Daily Total” in Item Number column. If daily line utilization exceeds 100% Total line will be colored in red.

5) There are might be line changeover times when production is switched from one item to another. Since line changeover time affects line capacity and utilization, line changeover times are downloaded too. Changeover information is displayed between appropriate lines (sequences) in the schedule. Item Number will always be a “CHANGEOVER”.

For changeovers

- Due Date is a date changeover applies to

- Line load is equal to a changeover time

- Line capacity is calculated the same way as for line schedules (as total capacity per day: duration of all shifts plus adjustments, if any)

- Line Utilization is also calculated the same way as for line schedules (as a percent of line load from the total line capacity)

With Line Schedule Download user gets much more information for each schedule line comparing to what he/she could get from standard 18.22.1.10 screen. This information allows user to make an informed decision on changes to production schedule.

Line Schedule Update

Line schedule could be updated either from 23.8 Planned Repetitive Sched Approve based on MRP results or from Line schedule WB interface.

The following columns on the Line Schedule tab could be updated:

- Sequence

- Item Number

- Quantity Scheduled

- Due Date (for new lines)

- New Seq (when changing item priority and moving it up or down in schedule)

- Delete

Modifying existing line in Line Schedule

User will be able to modify the following in the existing line schedule:

- Quantity Scheduled and

- Sequence (by putting new sequence value in New Seq column)

When user clicks on Update Schedule button after modifying quantity scheduled or assigning new sequence number (in New Seq column) system will compare sequence, item number, quantity scheduled and new sequence values from the spreadsheet with values in QAD.

If item and sequence exist, but quantity scheduled is different or new sequence is not blank, corresponding Line Schedule line in QAD will be updated.

If item and sequence do not match any record in existing line schedule system will treat line as new (see Add section below for details on adding new line to the schedule).

Due date for existing schedule lines is not updated. Production for the item could be shifted either by changing its sequence or by deleting and re-creating schedule line (with new due date) (these are QAD limitations).

Adding new line to Line Schedule

To add new line to the schedule the following values should be entered

- Sequence

- Item Number

- Quantity Scheduled

- Due Date

When user clicks on Update Schedule button after modifying quantity scheduled or assigning new sequence number (in New Seq column) system will compare sequence, item number, quantity scheduled and new sequence values from the spreadsheet with values in QAD.

If item and sequence entered do not match any record in existing line schedule system treat line as new and will try to add line to line schedule.

Prior to adding new lines to a schedule system validates sequence number, item number, quantity scheduled and due date:

- sequence number should not exist and should not be equal to zero

- item number should be defined in item number, be assigned to a production line ( in 18.22.1.1 Production Line Maintenance) and have allocation percentage set properly (in 18.22.1.11 Line Allocation Maintenance)

- item status should allow it to be used in repetitive (transaction ADD-RE should not be restricted for it)

- quantity scheduled should be a positive number

- date could be blank (then it is assigned a current date) or it should be a valid date equal or greater than Start Date in the selection criteria AND in Production Line Maintenance

Lines with blank value in the item number column are considered empty and will be ignored. Empty line signals the end of data. Lines that follows empty line on the spreadsheet (field Item Number is blank), if any, will be ignored during update too.

Deleting line from Line Schedule

To delete line from the schedule user will need to put “y” or “yes” in the Delete column.

When user clicks on Update Schedule button and schedule line has value “y” or “yes” in the Delete column its “Delete” flag in QAD is updated and line will be deleted next time user will click on Recalculate button.

Line Schedule Recalculate

User need to click on Recalculate button to trigger QAD line schedule recalculation function and to shift production based on line capacity.

Recalculation

- recalculates sequence numbers (if there were any sequence changes)

- recalculate scheduled quantities according to line capacity (line capacity might have been modified by changing number of shifts or their duration, adding line changeover, etc.) and production rates

After recalculation is complete line schedule is automatically downloaded and refreshes existing data on the Line Schedule tab (as if user clicked on Download Line Schedule button).

Here are some examples when recalculation is necessary:

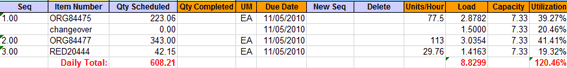

1) 1.5 hours line changeover time has been added when production is switched from item ORG84475 to ORG84477. If recalculation is not run, when user downloads line schedule total daily line utilization will exceed 100% and Daily Total line will be displayed in red;

2) Duration of the shift for a certain date is changed from 7.33 to 6 hours. If recalculation is not run, when user downloads line schedule total daily line utilization will exceed 100% and Daily Total line will be displayed in red;

3) Production rate for item ORG84475 has been increased. If recalculation is not run, when user downloads line schedule total daily line utilization will be less than 100%. Only when recalculation is run system will schedule some additional production for this date to reach 100% utilization (to efficiently use available production resources)

Planned Orders Report

When user clicks on Planned Order button (when standing on a specific item) pop-up window will appear showing a list of planned orders for a selected item, site and production line.

Note: This version of Line Schedule Workbench interface does not include Production Orders Approval functionality

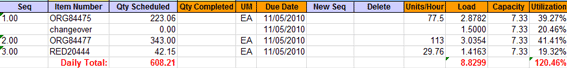

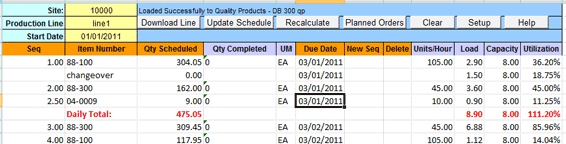

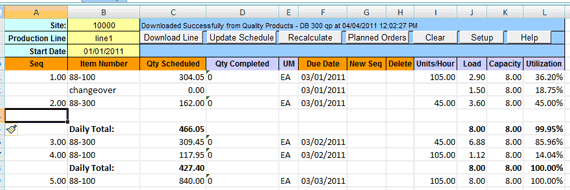

Example of Line Schedule Update

To schedule additional quantity on a specific date user need to insert empty line at a required day,

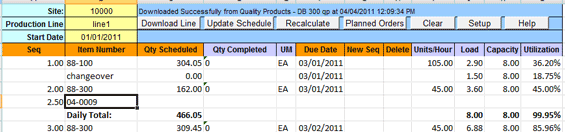

Type schedule sequence (it is decimal one in this example to schedule production for this specific day after a specific item) and item number.

User could click on Planned Orders button to see what quantity MRP needs for this item

For this example quantity of 9 and due date 03/01/11 are used

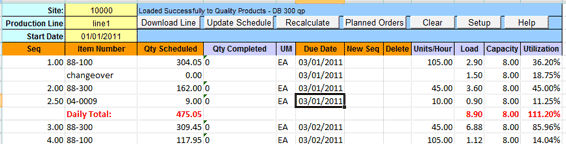

To populate data into QAD and initiate capacity check user need to click on Update schedule.

Item has been scheduled, but there is not enough capacity on that day. When daily total capacity exceeds 100% daily total linen gets highlighted in red.

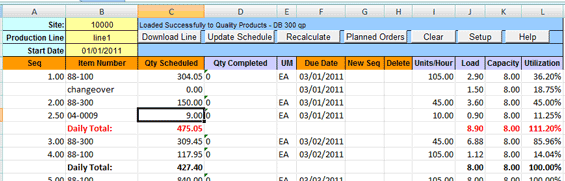

In this example user has a number of options:

1) move production of 04-0009 to the following day

2) decrease scheduled quantity for one of the other items that are produced on the same line at that day

3) Add one more shift or increase a duration of the existing shift (add overtime)

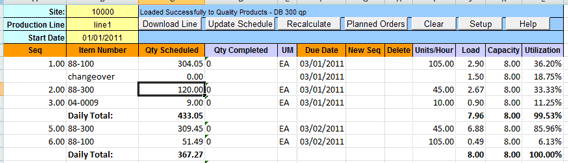

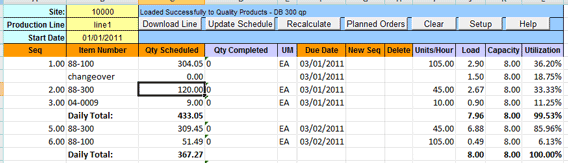

By selecting option 2 user decreases quantity for item 88-300 to 120.

Then user should click on Update to see if this change agrees with available daily capacity.

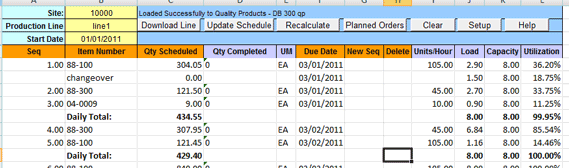

User, in this example, gets a result he/she wanted and it is within daily capacity limits. Now user should click on Recalculate (optional) to let QAD run validation and optimize line utilization. QAD will try to reach 100% line utilization. So if there is the same item scheduled for production for a next day QAD will try to shift production for today to utilise the line 100%.

In this example QAD automatically increases schedule for 88-300 to 121.5 to reach 100% line utilization and decreases quantity scheduled for the following day.

If user does not want to let QAD optimize a schedule he/she could skip recalculation step.

If user needs to delete schedule line he/she should just put “y” in the delete column and click on Update and Recalculate (optional).

Frequently Asked Questions

Do I need to do any set-up in QAD prior to using Line Schedule Workbench loader?

You won’t need to do any loader specific setup in QAD. However, there are number of prerequisites that should be met to be able to use Line Schedule Workbench functionality in QAD (whether though QAD users interface or with a loader):

- Item number should be defined in Item Master

- Item should be assigned to production line ( in 18.22.1.1 Production Line Maintenance)

- Item should have allocation percentage set correctly (in 18.22.1.11 Line Allocation Maintenance)

- Item should have status that will allow it to be used in repetitive (transaction ADD-RE should not be restricted)

How to add item to line schedule?

Insert an empty line where you want to add new line to a schedule.

Type sequence number in column Seq type. It should be higher than sequence for a line above, but lower than sequence for a line below, for example 2.5. Enter item number, quantity and due date. You could click on Planned Orders button to see what quantity MRP needs for this item

Then click on Update button to populate new line into QAD.

Line load and utilization will be calculated automatically if upload is successful.

How to delete Item from line schedule?

To delete line from the schedule put “y” or “yes” in the Delete column.

When you will clicks on Update Schedule button all lines with value “y” or “yes” in the Delete column will have their schedule “Delete” flag in QAD updated. Lines will be completely deleted from schedule next time you will click on Recalculate button.

How to move item within line schedule?

Due date for existing schedule lines could not be updated. It is QAD restriction. Line schedule for an item could be shifted by changing its sequence and/or by running recalculation.

To move line in a schedule assign new sequence in New Seq column and click on Update. New sequence should be higher than sequence for a line above and lower than sequence for a line below.

How to maintain line utilization?

Line utilization could be maintained within certain limit by changing sequence and/or quantity scheduled, or by running schedule recalculation.

For example, newly added line for item 04-0009 caused line utilization to go over 100%.

You could click on Recalculate button and let system decide when this item could be produced. For the above example system will split quantity for item 04-0009 between two days 03/01/2011 and 03/02/2011.

Or you could change quantity scheduled for item 88-300 and click on Update and Recalculate (optional)

Another option would be to assign lower sequence for item 88-300 in column New Seq and click on Update and Recalculate (optional).

If recalculation is run for this example, and because there is quantity scheduled for 88-300 for the following day, it will optimize line load and will move some quantity from 03/02/20011 to 03/01/2011 to reach 100% line utilization.

You could also extend duration of a shift for that day and add overtime hours in QAD (without changing sequences or quantities in line schedule) and then click on Recalculate (mandatory). Recalculate will identify changes in shift duration and re-calculate (show increased) line capacity of that day.

Is line schedule protected from unauthorized update?

Only users who have valid User ID and access to 18.22.1.10 Line Schedule Workbench menu and selected site could update line schedule. If user is not authorized to update line schedule error message “User is not authorized to update line schedule for site XXXX ” is displayed”.

How line load, capacity and utilization are calculated?

Line load (number of hours necessary to produce scheduled quantity) is calculated as scheduled quantity divided by Units per hour.

Line capacity is calculated as total capacity per day: duration of all shifts plus adjustments, if any.

Line Utilization is calculated as a percent of line load from the total line capacity (line load / line capacity * 100)

Totals for quantity scheduled, line load and line utilization are calculated for each date. Total lines are displayed with value “Daily Total” in Item Number column. If daily line utilization exceeds 100% Total line will be colored in red.

Is line setup time taken into account during line capacity and utilization calculation?

Line capacity is a fixed number expressed in hours. It is based on total duration of shifts for the day. When there is a product switch on a line, that requires setup/maintenance time, line changeover should be defined in QAD. Changeover information is displayed between appropriate lines (sequences) on line schedule with item number “CHANGEOVER”. Changeover time is added to line load time and is reflected in line utilization.

Why not all schedule lines from a spreadsheet have been uploaded into QAD?

Lines with blank value in the item number column are considered empty and will be ignored. Empty line signals the end of data. Lines that follows empty line on the spreadsheet (field Item Number is blank), if any, are be ignored during update.

What is Recalculate button?

Click on Recalculate button triggers QAD line schedule recalculation function and shift production based on line capacity. It is when

- QAD recalculates sequence numbers (if there were any sequence changes)

- QAD recalculate scheduled item and quantities for each day according to line capacity (line capacity might have been modified by changing number of shifts or their duration, adding line changeover, etc.) and production rates

What is the difference between Update and Recalculate?

Click on Update button record changes to line schedule, but does not perform a whole line schedule recalculation.

Click on Recalculate button triggers recalculation of sequences and shifts production based on line capacity and load.

Having Update and Recalculation as separate functions allows user to have more control over line schedule (as opposite to letting QAD decide when to schedule production based on existing setup).

Recalculation is optional, but there are certain cases when user should run it to have accurate line schedule. Here are some examples:

1) 1.5 hours line changeover time has been added when production is switched from item ORG84475 to ORG84477. If recalculation is not run, when user downloads line schedule total daily line utilization will exceed 100% and production will not be automatically shifted to the following day;

2) Duration of the shift for a certain date is changed from 7.33 to 6 hours. If recalculation is not run, when user downloads line schedule total daily line utilization will exceed 100% and production will not be automatically shifted to the following day;

3) Production rate for item ORG84475 has been increased. If recalculation is not run, when user downloads line schedule total daily line utilization will be less than 100%. Only when recalculation is run system will schedule some additional production for this date to reach 100% utilization (to efficiently use available production resources)

Learn more about Excel Loaders for QAD.